Custom Batteries, OEM Battery Packs: Benefits and Processes

At StorTronics, we specialize in designing and assembling custom battery packs tailored to meet the unique power requirements of our clients across industries including medical, military, and industrial manufacturing. Whether you need a primary or rechargeable (secondary) battery solution, our engineering team delivers battery packs that ensure performance, reliability, and compliance.

Benefits of Custom Battery Assemblies

Optimized Performance

Our custom battery packs are engineered for precise voltage, current, and capacity requirements, ensuring peak device performance and longer lifespan.

Space and Weight Efficiency

Tailored battery designs allow for compact, lightweight configurations that perfectly fit within your product dimensions.

Enhanced Reliability

Using top-quality components and stringent testing protocols, we deliver battery solutions you can trust—even in mission-critical environments.

Regulatory Compliance

We design and test our battery packs to meet industry standards, streamlining your path through regulatory and safety certifications.

Featured Custom Battery Pack Examples

GE Fanuc

A98L-0031-0025

6V battery pack designed for CNC machinery and robotics applications

Delivers stable voltage with excellent cycle life

A98L-0031-0011-L

3.6V Lithium battery for Fanuc controllers

Compact and reliable with long shelf life

Okuma

E5503-867-001

3.6V Lithium battery used in CNC and factory automation systems

High energy density for extended equipment uptime

E8049-090-012

Reliable custom battery pack for specialized machine tool controls

Durable construction for industrial environments

E5503-07E-001

Long-life lithium solution for Okuma CNC equipment

Designed for consistent performance and longevity

Motoman

149689-1

Custom battery pack for Motoman robotic arms

Provides reliable power to maintain memory and control settings

142189-1

High-performance battery for automation and robotics

Engineered for durability in demanding conditions

479348-2

Replacement battery pack for Motoman systems

Compact and robust with easy integration

Our Custom Battery Pack Development Process

1. Consultation

We begin with a detailed consultation to understand your product’s power needs, environmental conditions, and regulatory requirements.

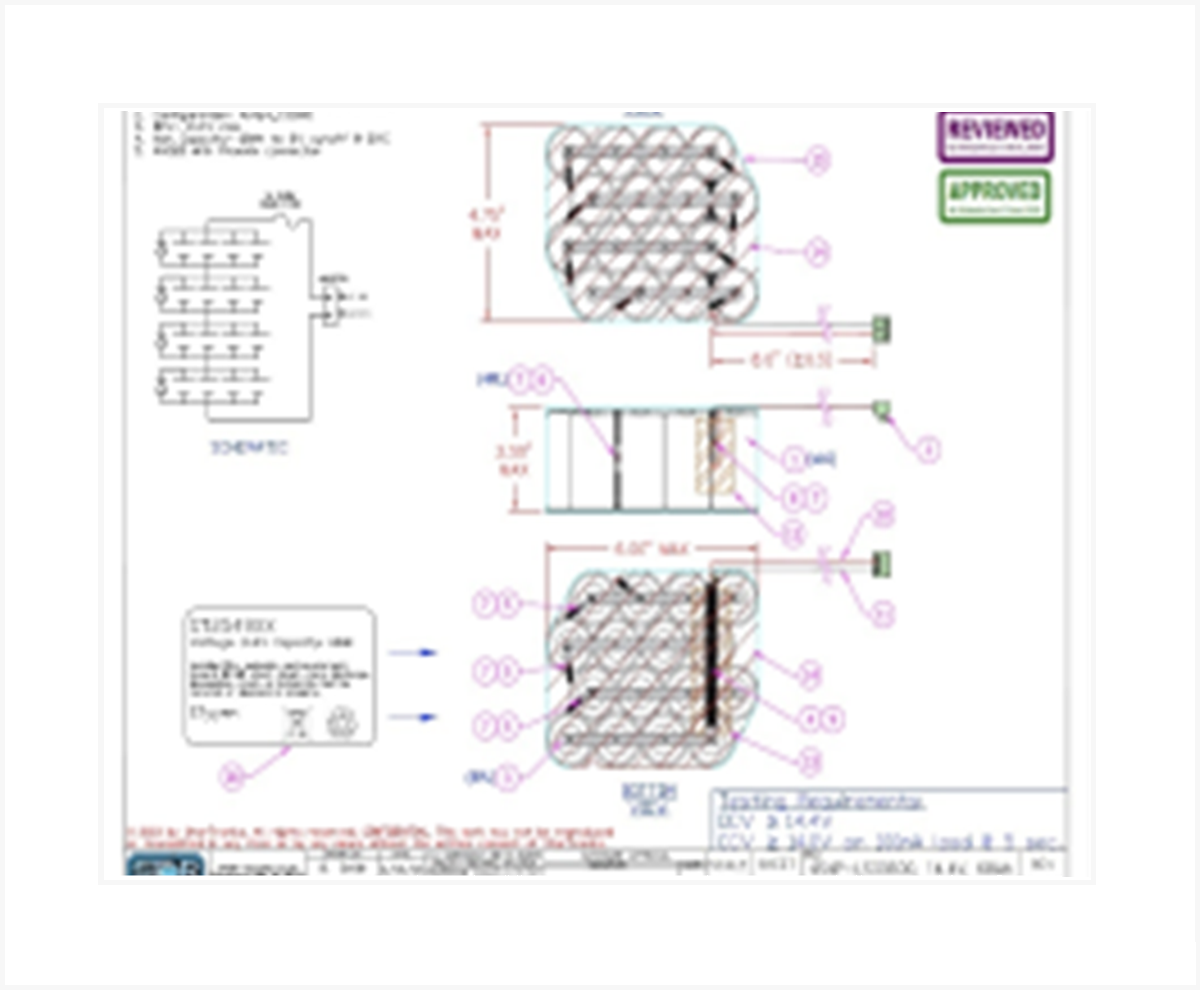

2. Design & Engineering

Our in-house engineers develop optimal battery configurations using the right chemistry, size, and components for your application.

3. Prototyping

We build functional prototypes so you can test and validate performance before moving to production.

4. Testing & Quality Assurance

Each battery pack undergoes comprehensive electrical and safety testing to meet your standards and regulatory expectations.

5. Production & Delivery

Upon approval, we manufacture and deliver high-quality battery packs with consistent performance and full traceability.

Ready to Build Your Custom Battery Solution?

Contact our team today to start your custom battery pack project. Use our custom battery design forms for both primary and secondary packs, or get in touch with one of our engineers to discuss your application in detail.

[Contact Us] [Primary Battery Design Form] [Secondary Battery Design Form]