THE DESIGN ENGINEERING PROCESS FOR CUSTOM BATTERY ASSEMBLIES

The process for custom battery assemblies involves several stages, which can be summarized as follows:

Requirements

In this stage, our Battery Pack Design forms (Primary [Non-rechargeable] or Secondary [Rechargeable]) will be provided and then our Applications and Design Engineer will work with the client to review the information about the battery assembly requirements. These will include items such as power output, voltage, capacity, size, weight, and application. We will also consider factors such as temperature range, charging time, discharge rate, and environmental conditions.

Conceptual Design

Based on the requirements gathered, our engineering team will develop a conceptual design(s) for the battery assembly. This would involve selecting the appropriate battery chemistry, cell configuration, and packaging options. The conceptual design will be evaluated based on various factors, such as cost, performance, and durability.

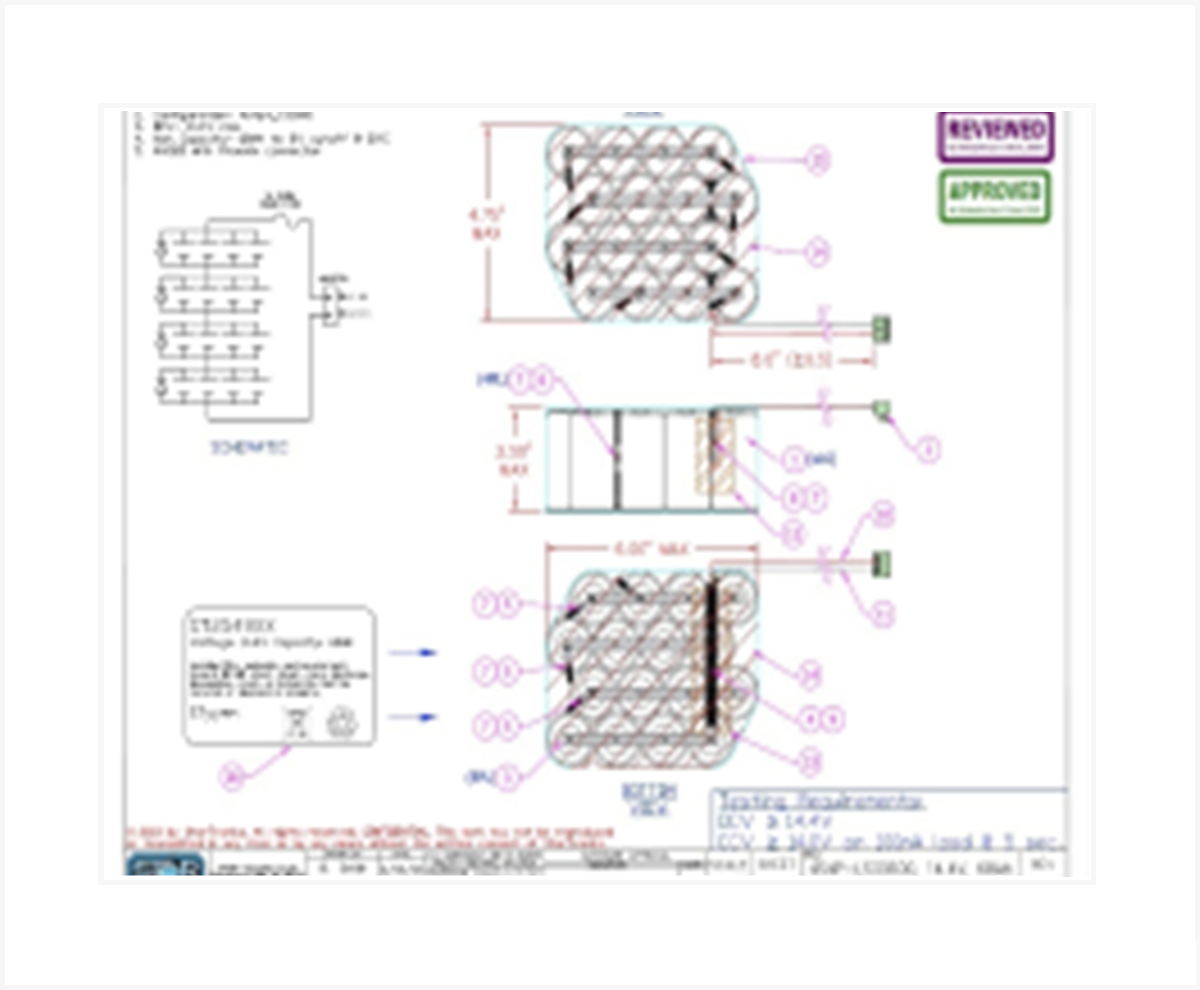

Detailed Design

The Applications and Design Engineer will then develop a detailed design for the battery assembly. This will involve creating dimensional design drawings, selecting the specific components, and designing the electronics and bill of materials.

Prototype Development

With the detailed design completed, the customer will then approve an order for engineering prototypes for review. The engineering team will then build the required prototype of the battery assembly. This will involve assembly, testing and verifying the performance of the battery.

Testing and Validation

The prototype will then undergo testing and validation if required to verify it meets specifications. This may involve testing for temperature and humidity testing, as well as functional testing, including cycling and performance testing.

First Articles of Approval

Once the prototype has gone through the Design, Prototype Development and Testing the prototypes are sent to the customer for approval. The First Article of Approval will allow the customer to see the finished product and install and test it in their application.

Production

Once the First Article has been approved, the engineering team works with our production team to produce the battery assembly for production levels required by the customer. This involves developing the manufacturing processes, work instructions, procedures and ensuring that the quality of the battery assemblies are consistent.

Quality Control

Throughout the production process, the engineering team will perform quality control checks to ensure that the battery assemblies meet the required specifications. This includes inspecting the components, in process validation and testing the finished battery assemblies.

Delivery and Support

Once the battery assemblies are completed, they will be delivered to the customer based on their requirements. The engineer may also provide ongoing support to the customer to ensure that the battery assemblies continue to perform as expected.

|